Company Profile

Company introduction

Be an expert inductor supplier. Not only automated, No operator factory and smart QA system in FJ.

Auto made in our product

Competitive pricing for our customers

The highest quality products

Shortest lead times

Outstanding customer service

Fully automated production

Power Inductor Manufacturer

Feng Jui Technology Co., Ltd. is an experienced, industry-recognized, global power inductor supplier manufacturer based in Taiwan. We supplying SMD Inductors, Automotive Inductors and Power Inductors with superior quality at a competitive price. In addition to SMD Inductors, we also produce high standard Ferrite Chip Inductors, Wound Chip Inductors and Ceramic chip Inductors Aside from the above products, we also support Automotive Power Inductors , Flat Wire Power Inductors , Common Mode Chokes, and Dip Power Inductors. For more information on any of our products, please contact us.

History

1998: Initiated SMD Power Inductor production.

1999: A new 6000 m2 plant in Guangdong came on-line.

2000: Our China plant obtained ISO-9002 Quality Assurance Certification.

2001: Plant expands to 12000 m2, - with a 1000 employee workforce.

2002: Initiated Slim power inductor production, receiving outstanding reviews from our customer feedback.

2006: Upgraded our production process to a fully automated system.

2007: Further upgraded our production line to run Halogen free product.

2008: Established Hong Kong branch office.

2009: Our Guangdong plant awarded international QC080000 Certification

2010: Developed auto machine in house

2011: Adopted bar code monitor system in our production

2012: Awarded AEC-Q200 certification for our components.

2013: Relocated our head office to Zhongli District, Taoyuan, Taiwan.

2014: Began production for Medical and automotive application

2015: Established Korea branch office

2015: Expanded the full product series to AEC-Q200 standard

2016: Began full series common mode choke production

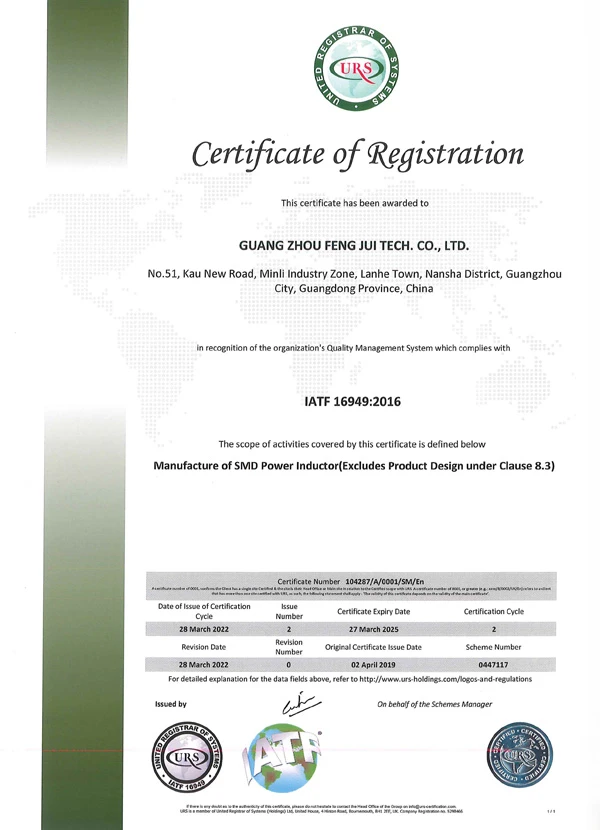

Our Guangdong plant awarded international IATF 16949 Certification

2017: Expanded the Taiwan headquarter area from 4000 m2 to 10000 m2

2018: Expanded sales to Indian market

2019: Completed expansion plan with new building and production line in Taiwan

2020: Import Inducstry 4.0 as common mode inductor

2021: Build QC on-line system as SQM,TQM,SPC...etc.

2022: Plan ISO 45001 system

Environmental commitments

- Purpose:

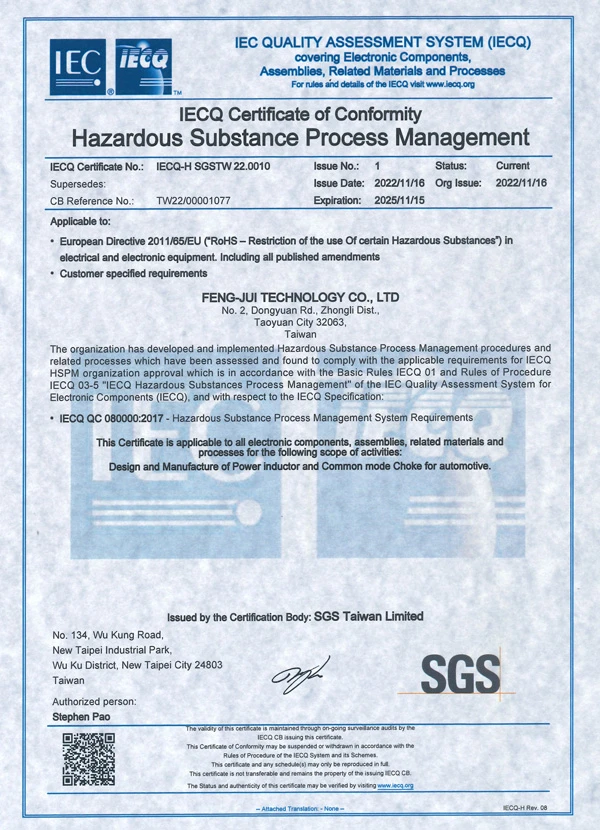

- In response to global environmental legal requirements, Feng-Jui TECHNOLOGY has developed 「QPQA07 Restricted Hazardous Substances Control Procedures」 in order to regulate the use of restricted materials during the production of Feng-Jui TECHNOLOGY products, comply with any environmental regulations, and to reduce the impact on the ecosystem.

- In addition to complying with the requirements of regulating the use of restricted substances, we are continually monitoring for any developments in the international environmental movement including: EU directive to ban electrical and electronic products (RoHS); EU - Chemical substance registration, evaluation, authorization and control (REACH); Halogen free specification in the industry; based on respect for the stance on international human rights (conflict minerals); USA California Proposition 65; United Nations Environment Programme, UNEP Stockholm Convention on Persistent Organic Pollutants(POPs); Norway product regulations which prohibits the consumption of products that contain certain hazardous substances (PoHS) and so on.

- With regards to the impact on the environment, if there are regulations beyond the scope of the above, we expect our suppliers to uphold its commitment to environmental protection. We ask that suppliers must comply with the relevant requirements and regulations, and to fulfill the duty to inform Feng-Jui TECHNOLOGY of the status by then.

- Supplier Requirements and Corporate Responsibility:

- RoHS:

- Please provide Feng-Jui TECHNOLOGY with the final product’s raw material and a test report from a notary of a third party source to comply with RoHS (2011/65/EU) directives.

- In order to ensure that each supplier's manufacturing process, packaging, shipping and handling process do not produce RoHS restricted substance, test reports are valid for only one year.

- Corporate Responsibility:

- Exemption declarations are required if parts supplied to Feng-Jui TECHNOLOGY are referenced by exclusionary terms.

- PFOS/PFOA:

- Please provide Feng-Jui TECHNOLOGY with the final product’s raw material and a test report from a notary of a third party source to show compliance of the PFOS/PFOA Directive (2006/122/EC).

- In order to ensure that each supplier's manufacturing process, packaging, shipping and handling process do not produce PFOS/PFOA restricted substance, test reports are valid for only one year.

- Halogen Free:

- Please provide Feng-Jui TECHNOLOGY with the final product’s raw material and a test report from a notary of a third party source which comply with the specifications in line with the industry standards for products contacting halogen.

- REACH:

- Information refer to web address at http://echa.europa.eu

- If there are difficulties in providing the test report, it is acceptable to sign the Feng-Jui TECHNOLOGY provided contract stating the absence of restricted substances or provide us with the「REACH Compliance Declaration」

- In response to REACH's specifications, Feng-Jui TECHNOLOGY needs the supplier’s to provide all chemicals that are utilized during manufacturing. The IMDS provided must also include the CAS No.; To acknowledge the parts, we require your company to provide us with the IMDS.

- Corporate Responsibility: If your company manufactures or imports a total weight of over one ton on an annual basis to Europe 「chemicals」, then you are required to register on the website before 2018/05/31.

- Conflict Minerals: If your International Material Data System includes Sn、Ta、W、Au:

- In response to Bill H.R. 4173 Dodd-Franck Act signed by U.S. President Obama on July 2010, if the use of Tin (Sn), Tantalum (Ta), Tungsten (W) or Gold (Au) metal mineral resources are present, then we need to confirm whether the source of the material is from the Democratic Republic of the Congo; Please reply CMRT to Feng-Jui TECHNOLOGY.

- RoHS:

- Regulatory Directive Limits:

- RoHS:

RoHS Directive 2011/65/EU:- Cadmium (Cd) <100ppm

- Lead (Pb) <1000ppm

- Mercury (Hg) <1000ppm

- Hexavalent Chromium (Cr(VI)) <1000ppm

- polybrominated biphenyls (PBBs) <1000ppm

- polybrominated diphenyl ethers (PBDEs) <1000ppm

- Dis(2-ethylhexyl)phthalate (DEHP) <1000ppm

- Butyl benzyl phthalate (BBP)<1000ppm

- Dibutyl phthalate (DBP)<1000ppm

- Di-isobutyl phthalate(DIBP)<1000ppm

- PFOS/PFOA:

The permissible maximum concentration values of hazardous substances present in electrical and electronic equipment, general requirements are as follows:- Substance or constituent of preparations < 10ppm

- Semi-finished products & articles & parts < 1000ppm

- Textiles & other coated materials < 1ug/m2

- Halogen Specifications:

The supplier shall comply with the following Halogen specifications: IEC 61249-2-21、JPCA-ES01 2003、IPC 4101:- Chloride (Cl) <900ppm

- Bromide (Br) <900ppm

- Total Halogens contained (Cl+Br)<1500ppm

- REACH:All of product contain SVHC <1000ppm.

- RoHS: